AP Sets a New Standard

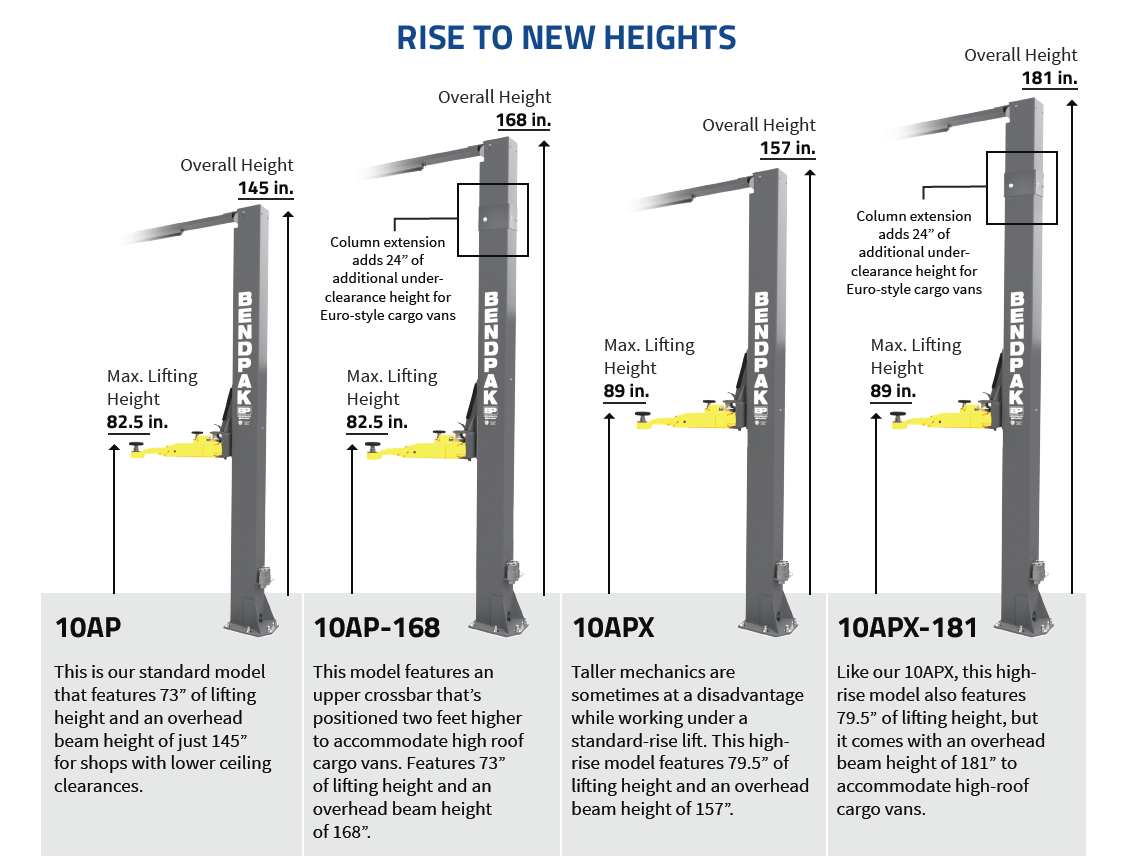

As the automotive industry embraces cutting-edge technology, staying ahead in the repair and maintenance sector requires tools that can keep up. That’s where BendPak’s AP Series come in – a game-changer that ushers in a new era of car lift engineering. Meticulously designed to fuse the best features of existing lift types into an innovative concept, these lifts are the answer for extreme usage, heavy loads, and operator safety. The 10AP-168 offers all the advantages you’ll find in the AP Series with an added 168” height for mechanics to work in comfort and ease.

Redefining Expectations with BendPak’s AP Series

For auto repair shops seeking versatile options, the AP Series by BendPak is the ultimate solution. This sturdy, dependable car lift effortlessly combines wide and narrow installation choices into a single customizable package. With expandable top beams and innovative Bi-Metric™ arms, this lift adapts to any vehicle lifting need, whether symmetric or asymmetric. Striking a balance between simplicity and sophistication, this intelligent design minimizes service and maintenance costs, reducing operating expenses and boosting productivity.

Automatic Arm Restraint System

Traditional swing arm restraints have their place, but BendPak takes safety a step further. The Automatic Swing Arm Restraint System (ASARS) of BendPak’s AP Series has been designed to withstand the forces exerted by shifting vehicles during loading or service. Built from forged steel, this adaptive system delivers over 2000 pounds of load-holding force. With a 360-degree grip, this patented restraint system ensures arms stay securely in place, preventing unplanned movement. The quick-release operator lever adds an extra layer of control.

The Future is Triple-Telescoping

Innovation takes shape with patented triple-telescoping swing arms, revolutionizing lifting precision. Unlike conventional arms, AP arms retract shorter and extend farther, offering lift operators versatile arm positioning. The three-stage design, complete with a patented nesting feature, allows for greater retraction and extension. Inner sliding arm movement reaches new levels of efficiency, ensuring precise lifting action without hindrance.

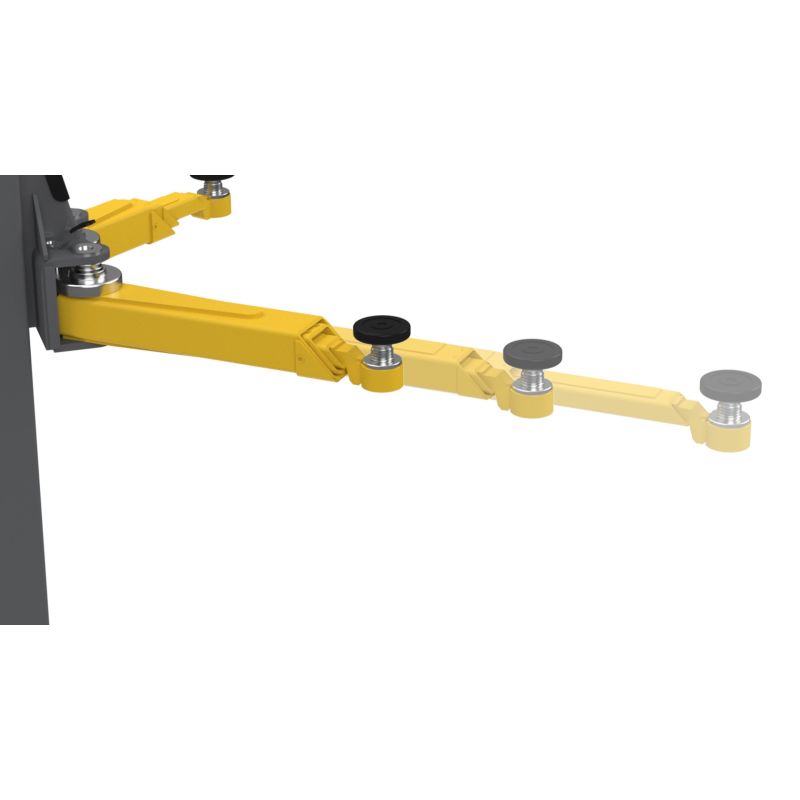

Low-Pro™ Swing Arms

Engineered for ultimate versatility, BendPak’s exclusive Low-Pro™ swing arms shine in servicing lowered chassis-height vehicles. Telescoping channels and a dropped-end pad receiver grant easy access to challenging lift points while safeguarding vehicle side skirts and ground effects. Paired with height stackable adapters and two-stage spin-up screw pads, the system guarantees secure vertical pad placement. With screw adapters featuring polyurethane pads resistant to wear, achieve impeccable lifting alignment in all conditions. Optional stackable adapters further enhance precision and support.

Bi-Metric Swing Arms

BendPak’s Bi-Metric swing arms, exclusively designed for unmatched flexibility. Capable of symmetric or asymmetric setups, these arms eliminate the need for switching, accelerating vehicle servicing and boosting operational speed. This groundbreaking innovation redefines lifting standards, enhancing safety, efficiency, and versatility for auto repair shops. Equip your shops with the latest in lifting technology and experience the difference firsthand.

Features

- Durable Powder Coat Finish

- Expandable Top Beam Accommodates Wide or Narrow Drive-Through Configurations

- Double-Telescoping Screw Pads Offer Increased Versatility

- Padded Overhead Safety Shutoff Bar

- Exclusive Bi-Metric Arm Design for More Versatile Arm Positioning

- Single-Point Safety Release

- Drop-End Arms Provide a Lower Pad Height

- Dual Hydraulic Direct-Drive Cylinders

- Oversized Tall Carriages for Superior Strength and Durability

- Electric / Hydraulic HVLP Power System

- Self-Lubricating Dura-Glide UHMW Polyethylene Bearing System

- Safety Locks in Each Column Spaced Every 3”

- Automatic Arm Restraints Withstand Over 2000-Pounds of Side Force

- Heavy-Duty ½” Aircraft-Quality Equalizer Cables

- Oversized Cable Sheave Diameter Reduces Cable Fatigue

- Four Triple-Telescoping Arms

- ALI Certified

Specs

- Lifting capacity: 10,000 lbs. / 4,536 kg

- Max. Capacity: 5,000 / 2,268 kg (Front Axle)

- A – Max. Rise: 75.5 in. / 1,918 mm

- B – Lifting Height: 79.5 in. / 2,019 mm

- C – Max. Lifting Height: 89 in. / 2,261 mm

- D – Min. Height: 4 in. / 102 mm

- E – Overall Height: 168 in. / 4,267 mm

- F – Overall Width: 135 in. / 3,431 mm (Narrow)

- G – Outside Columns: 127.5 in. / 3,238 mm (Narrow)

- H – Inside Posts: 108.5 in. / 2,756 mm (Narrow)

- I – Drive-Thru: 97.5 in. / 2,476 mm (Narrow)

- J – Floor to Top Switch: 163 in. / 4,140 mm

- K – Front Arm Reach: 24.5 in. / 622 mm (min)

- L – Rear Arm Reach: 32 in. / 812 mm (min)

- Max. load per Lift Arm: 2,500 lbs. / 1,134 kg

- Screw Pad Adjustment: 2 in. / 51 mm

- Time to Full Rise: ≈ 45 seconds

- Motor: 220 VAC, 60 Hz, 1 Phase

- Sound: <70 dB